Shade house

Shade house

A Shade house is a structure enclosed by agro nets or any other woven material to allow required sunlight, moisture and air to pass through the gaps. It creates an appropriate micro climate conducive to the plant growth. It is also referred as shade net house or net house.

Uses of shade house

- Helps in cultivation of flower plants, foliage plants, medicinal plants, vegetables and spices.

- Used for fruit and vegetable nurseries as well as for raising of forest species etc.

- Helps in quality drying of various agro products.

- Used to protect against pest attack.

- Protects from natural weather disturbances such as wind, rain, hail and frost.

- Used in production of graft saplings and reducing its mortality during hot summer days.

- Used for hardening tissue culture plantlets

Planning for a shade house

The shade house structure should be planned taking into consideration the type of crop to be grown, locally available materials and local climatic conditions. The provision for future expansion should be there.

Site selection

A shade house should be located in such a way that it is well connected with market for input supplies and sale of its produces. This structure should be constructed away from buildings and trees, so also away from industrial or vehicular pollutants. The site should be free from drainage problem. There should be provision of electricity and good quality water. However, wind breakers may be located 30m away from the structure.

Orientation

There are mainly two criteria for shade house orientation. They are the uniformity of light intensity in the shade house and wind direction. Single span structure may be oriented either in east-west or north-south direction but multispan structure should be oriented in north-south direction to ensure uniform light intensity.

Structural materials

A shade house structure composed of two basic components i.e. frame and cladding material. The shade house frame provides support for cladding material and designed to protect against wind, rain and crop load. The shade house mild steel (ms) angle frame lasts up to 20 to 25 years, if anti rust treatment is done at regular interval, whereas bamboo structure can last up to 3 years. The agro shade net lasts for 3 to 5 years depending on the climatic condition. Shade nets are available in different colours with wide range of shade percentages viz. 25%, 30%, 35%, 50%, 60%, 75% and 90%.

The design of shade house frames depend on the need and engineering skill. Structural frames of quonset, gable or gothic arch shape or with minor modification suitable to local condition are recommended in high rainfall areas like Orissa.

Design and Construction of shade house

Two types of shade house designs have been developed at Precision Farming Development Centre, Orissa University of Agriculture and Technology, Bhubaneswar. The principal advantage of these shade houses is that these structures do not require any welding at the site. Another advantage is that foundation posts have been chosen to protect these structures against termite attack. The details of these shade houses are mentioned below.

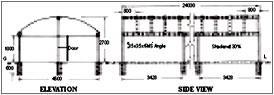

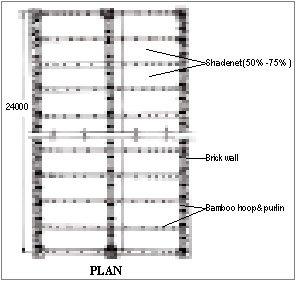

Shade House - I

This design (Fig. 1) makes use of ms angle (35mm x 35mm x 6mm) and bamboo as structural frame. The ms angles are used as foundation posts with provision for grip at the bottom and ‘U’ clip for holding bamboo at the top. Bamboo is used both as purlin and roof structure. The levelling of shade house site is done followed by layout of the plan. The digging of pits for foundation posts are done, a portion of pits are filled with sand and compacted well. Then foundation posts are fixed with cement concrete, maintaining proper alignment in three parallel rows. After proper curing, bamboo sized to proper dimension is used as purlin, roof arch structure (hoops) and are tied properly. Pre-fabricated end frame and door frame are fixed to the structure with nuts & bolts. Then agro shade net of 50% - 75% is fixed to the roof and nets of 30% are fixed to the side frame. The in end frames and door are also covered with shade net. Lastly mid-pavement and boundary ridge line is constructed with brick masonary.

The unit cost of this type of shade house structure is about Rs. 225/Sqm. The materials used in this type of shade house are shown in table 1.

List of Materials (Shadehouse - I)

|

Sl. No. |

Particulars |

Item |

Specification |

Quantity |

|

1. |

Foundation Posts with "U" |

MS Angle Iron& |

35 mm x 35 mm x 6 mm |

209 Kg |

|

|

|

MS Flat |

25 mm x 6 mm |

7 kg |

|

2. |

Door System and end Frame |

MS Angle Iron |

35 mm x 35 mm x 6 mm |

71 kg |

|

3. |

Roof Structure |

Bamboo |

75 mm – 100 mm dia |

20 No |

|

4. |

Roof & Side Cover |

Agro shade net |

50% - 70% & 30% |

328 sqm |

|

5. |

Grouting of Foundation |

Cement Concrete |

1:2:4 with 12 mm chips |

1.3m3 |

|

6. |

Anti-Rust Treatment |

Enamel Paint & thinner |

- |

4 Litre |

|

7. |

Erection of Structure |

(i) Nuts & Bolts |

3/8”x1” |

1 kg |

|

|

|

(ii)GI Wire |

4 mm |

2 kg |

|

8. |

Pavement |

Brick Masonary |

Cement Mortar(1:6) |

2.4 m3 |

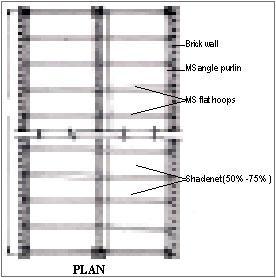

Shade House- II

This design (Fig. 2) makes use of ms angle (40mm x 40mm x 6mm) for foundation posts, purlins, end frame and door of shade house structure. The ms flat is used for hoops to support the cladding materials. The foundation posts are having provision for fixing with purlin and hoops by nuts & bolts. Similarly ms flat used as hoops are having provision for fixing with purlin. The levelling and layout of plan at site is done as in previous case. The foundation posts are fixed to the pits with cement concrete and curing is done for seven days. The fixation of purlin, hoops, end frame and door frame are done by using nuts & bolts.

Then nets are fixed to the structure. Lastly mid-pavement and boundary ridge line is constructed with brick masonary. The unit cost of this type of shade house structure is Rs. 500.00 /Sqm. The materials used in this type of shade house are shown in table 2.

List of Materials (Shadehouse - II)

|

Sl. No. |

Particulars |

Item |

Specification |

Quantity |

|

1. |

Foundation Posts |

MS Angle |

40mm x 40mm x 6mm |

336 Kg |

|

2. |

Purlin & end Frame |

MS Angle |

40mm x 40mm x 6mm |

305 Kg |

|

3. |

Door Frame |

MS Angle |

40mm x 40mm x 6mm |

41 Kg |

|

4. |

Hoops |

MS Flat |

30mm x 6mm |

159 Kg |

|

5. |

Roof & Side Cover |

Agro shade net |

50% - 70% & 30% |

328 sqm |

|

6. |

Foundation Grouting |

Cement Concrete |

1:2:4 with 12mm chips |

1.8 m3 |

|

7. |

Pavement |

Brick Masonary |

Cement Mortar(1:6) |

2.4m3 |

|

8. |

Erection of Structure |

(i) Nuts & Bolts |

3/8”x1” |

4 Kg |

|

|

|

(ii) GI Wire |

4mm |

4 Kg |

|

9. |

Anti-Rust-Treatment |

Enamel Paint & thinner |

- |

8 Litre |

Source : NCPAH

Last Modified : 3/1/2020

This topic covers information about Clove Crop Sta...

This topic provides information on Package of prac...

Covers information related to coffee production te...

This topic provides the package of practices for c...