Edible Oyster Farming in India

Edible Oyster Farming in India

Introduction

The oysters are highly esteemed sea food and considered a delicacy in USA, Europe, Japan etc. In India there is a growing demand for oyster meat in some parts of the country. It is said that ‘oyster’ is scientifically the best known marine animal. It is one of the most widely cultivated species. As early as the first century BC the Romans were the first to develop simple methods of collecting oyster seeds and growing them for food. The Japanese developed farming methods that yielded good results. The awareness about the vast potentialities for development of oyster farming in tropics is recent. Serious efforts are now being directed in its development under tropical conditions.

Main areas / locations having rich oyster beds / suitable areas for farming in Kerala are: Ashtamudi and Vembanad lakes, Cochin backwaters, Munambam estuary & nearby areas of Sathar Island, Estuaries and the creeks of Dharmadam, Valapatnam, Nileswaram and Chandragiri.

Oysters & their Biology

The shape of the oyster is extremely variable depending on the environment in which it is grown.

- Smooth and elongated when grown individually on soft substrata.

- Corrugated and circular shell with lower valve deep when grown individually on hard substratum.

- Irregular shape when grown with other oysters.

- Circular / elongated with reduced cupped nature when grown fixed to a firm substratum

Reproduction

In the genus Crassostrea sexes are separate but ccasionally hermaphrodites occur. During spawning, ripe eggs and sperms are discharged into the exterior where fertilization takes place. Temperature food availability and salinity are considered as important exogenous factors, in influencing the maturation of gonads. A single female measuring 80-90 mm spawns 10 to 15 million eggs at a time.

Condition Index

The condition index of the oysters denotes the quality of the meat and it is useful to determine the best period for harvest. It is also helpful to assess the suitability of a locality for culture. High condition indicates greater proportion of meat in the whole weight of the oyster; those in prime condition are tasty when compared to the flaccid and watery meats of oysters in poor condition.

The soft body of the oyster undergoes changes, which are usually related to the reproductive cycle. During the maturation process the gonad increases in weight resulting in increase in the weight of soft body. Before the commencement of spawning the condition index reaches high value and with the release of gametes, the soft body of the oyster looses weight. The condition factor is studied based on weight, volume of both. The percentage of wet flesh weight in total weight gives the condition.

Condition Index = Weight of dry meat weight x 1000 / Volume of shell cavity

In C. madrasensis the condition is considered as high if it is above 140 and poor if it is below 70.

Seed Collection

Oyster seed are collected from estuaries by placing suitable collectors called cultch in the water column at appropriate period. During spawning seasons the spat collectors are suspended from racks.

How to prepare a cultch?

Cultch is the term used for spat / seed collector. For suspended method of oyster culture cutch made of oyster shells have been found to be ideal. Empty oyster shells are cleaned manually to remove the foulers and then washed to remove silt. A small hole is made on the shell and these are strung on 3mm dia nylon rope with a spacing of 15 to 20 cm between each shell (5 shells per meter rope). Such strings are called ren. The spaced rens can be used as such for grow out system. For seed collection purposes the shells are strung continuously without spacers ( 10 to 15 shells per meter) and after the attachment of seed they shells can be removed and restrung at the rate of 5 shells per meter which is the ideal density for grow out. If the oysters are to be grown by the tray method then empty shells or lime coated tiles can be placed in the trays for seed collection. Lime coated tiles gave encouraging results and on a single tile, as many as 120 larvae are known to settle.

When to place the cultch for seed collection?

One of the main factors that determine the success of the farming operation is the period when the clutches are placed for seed collection. If they are laid in advance of spatfall, they may be covered with silt or settlement of foulers, making them unsuitable for the oyster larvae to settle. The larval period in C. madrasensis is 15-20 days. The ideal time for laying the spat collectors in the water is about 7 -10 days after peak spawning (as determined by gonad examination and abundance of early larval stages in the plankton). Strong currents interfere with larval settlement and may result in poor spat collection.

Selection of farm site

For site selection several factors are to be considered

| Parameter | Range | Methodology for determination of the parameter | |

|---|---|---|---|

| 1 | Salinity (ppt) | 10 to 38 | By titration or refractometer |

| 2 | Depth ( m ) | 1.5 – 4 | By sounding or manual |

| 3 | Temperature o C | 23- 34 | Using thermometer |

| 4 | Dissolved oxygen mg/l | 3–5 | Winkler method or by using probe |

| 5 | pH | 6.5 – 8.5 | pH meter or pH paper |

| 6 | Turbulence due to wave ( m) | < 0.5 to 1 | By observation and local enquiry |

| 7 | Water current m / second | 1–5 | Current meter or from literature |

| 8 | Clarity (m) | 0.5 –1.5 | By Sechii disc |

| 9 | Availability of seed | Within 100 m | By enquiry / observation |

| 10 | Local market | Average to good | By enquiry / observation |

| 11 | If free from various pollution like | Faecal | By enquiry /observation |

| Industrial | |||

| Agriculture | |||

| Sewage | |||

| Retting | |||

| Oil |

Sheltered areas offering protection from strong wave action are preferred. From intertidal region to areas extending upto about 5 m depth can be considered for adopting suitable culture method. Similarly the culture technique is adopted depending upon the type of substratum. On-bottom culture method is substrate-specific while off-bottom method has little to do with the nature of substratum. Large-scale moralities have been reported in salinities below 10 and above 40 ppt when the natural oyster populations of C. madrasensis were exposed for prolonged periods. The natural populations occur at a temperature range of 21 to 31oC.

Farming methods

They are broadly grouped as bottom (on bottom) culture and off-bottom culture. Raft, rack, long-line and stake are used in the various off-bottom culture practices. The off-bottom culture methods are advantageous over the bottom culture in the following respects.

- Relatively rapid growth and good meat yield.

- Facilities three-dimensional utilization of the culture area.

- The biological functions of the oyster such as filtration feeding etc. are carried out independent of the tidal flow,

- Silting and predatory problems are negligible.

On bottom culture

The oysters are grown either in the intertidal or subtidal area directly on hard substratum. For intertidal culture a minimum of 16 hours submergence is suggested to ensure adequate food supply. Oyster seed attached to the collectors are planted on the bottom and allowed to grow for the market. The disadvantages of this method are increased exposure to benthic predation, siltation and low production. In U.S.A. the production is estimated at 5 t/ha/year and in France 7.5 t/ha/year. This method is yet to be experimented in India.

Rack and Ren Method

It is also called ren method. The racks are constructed in 1 to 2.5 m, depth There are several variations in the types of racks. The single beam rack consists of a beam placed and secured to the top of posts driven into the bottom. A series of single beams are placed in a row. The crossbeam rack is constructed by placing cross bar on top of single posts and two long beams are secured on the end of cross beams. In the farm, the shell strings are suspended from racks. The mortality (including those fallen) is about 45%.

Rack and Tray Method

The nursery-reared single spat (cultch-free) measuring about 25 mm are transferred to trays of size 40 x 40 x 10 cm at a density of 150 to 200 oysterlings/ tray. The tray is knitted with 2 mm synthetic twine of appropriate mesh and is suspended from rack. Once the oysters reach 50 mm length they are segregated and transferred to rectangular tray of size 90 x 60 x 15 cm these trays are placed on the racks. Each tray holds 150 to 200 oysters. The average growth rate of the oyster is 7 mm/month and at the end of 12 months the oysters attain an average length of 85 mm in Tuticorin. The production is estimated at 120 t/ha/year. Compared to the string method, this method gives production but the production cost is high.

Stake culture

A stake is driven into the substratum and on the top end one nail and on the sides two nails are fixed. The nail holds in position a shell with spat attached. The stakes are placed 60 cm apart. In this method, the nursery rearing of spat is carried on the same stake . For about two months the spat on the top end of the stake are covered by a piece of velon screen. Once the oysters attain 25-30 mm the velon screen is removed and in another 10 months they reach the marketable size. The growth rate of the oysters in this method is the same as that of the oysters raised by the string method. The production is estimated at 20 t/ha/year.

Farm Management

Periodic checking of the farms is essential. The main points to be checked are replacement of broken farm structure and re suspending loosened rens which touch the estuarine bottom. High mortality rates have been observed when the rens fall on the ground. To tide over these problems periodic checking is essential.

Predaters and foulers are also a menace to oyster farmers. Crabs, fishes, starfishes, polychaetes and gastropods are the predators of oysters.

Barnacles are fouler that settles on the wooden structures, trays and oysters. It competes for food with the oysters. It also increases the weight of the ren causing damage to the farm structure.

Large scale moralities of oysters due to the diseases caused by the fungus Perkinsus marinus, and the protozoan parasite Minchinia nelsoni, have been reported from temperate countries.oysters in the natural bed at Tuticorin have been observed to be infected by P.marinus.

Harvest of oysters

The oysters are harvested when the condition is high. Along Kerala harvest is ideal during May in Vembanad and Chettuva estuary and during August – October in Ashtamudi Lake. Generally high condition index is obtained when the gonad is ripe prior to spawning. Harvesting is done manually.

Depuration

Oysters, like other filter-feeding bivalves, accumulate pathogenic organisms in their body. Members of the Salmonella group cause typhoid fever, while coliforms and vibrios cause gastroenteritis. By depuration the bacterial load is brought down to permissible levels, also faeces, sand particles and silt are removed from the alimentary canal of oysters.

The oysters are placed for 24 hours in cleaning tanks under a flow of filtered seawater. About 10-20% of the seawater is continuously replaced. At the end of 12 hours the water in the tank is drained and oysters are cleaned by a strong jet of water to remove the accumulated faeces. The tanks are again filled with filtered seawater and the flow is maintained for another 12 hours. Then the tanks are drained and flushed with a jet of filtered sea water. The oysters are held for about one hour in 3 ppm chlorinated seawater, and then washed once again in filtered seawater before marketing.

Transport and storage

Oysters kept under moist and cool conditions survive for several days. However it is desirable that they reach the consumer within three days of harvest. Studies indicate that oysters packed in wet gunny bags are safely transported for 25-30 hours without mortality and in good condition.

Shucking

The removal of the meat from the oyster is called shucking. A stainless steel knife is used for the purpose. To render shucking easy, oysters are subjected to a wide range of treatments such as exposure to week hydrochloric acid, heat cold, vacuum, microwaves and lasers. Freezing the oysters, or immersing them in hot water are the two methods commonly followed. However in India steaming the oysters for 5 to 8 minutes has been found to be ideal to make the oysters open the valves.

Processing

Oysters are eaten in fresh condition in the half shell in many countries. The oysters are processed in several ways.

Frozen oysters

After depuration whole oysters (shell-on) are frozen by spreading them in a single layer of trays in an air blast freezer with polypropylene film stretched over each tray. Frozen whole oysters packed in polythene bags remain in good condition for six months in cold storage at 25oC. The liquid within the shell acts as a glaze to protect the meat from dehydration.

Canned oysters

Oyster meat is chilled, washed and blanched in 3% brine containing 0.1% citric acid for 4 to 5 minutes. The balanced meat is packed in cans, and hot 2% brine with 0.1% citric acid is added to the cans. The cans are seamed, sterilized at 115o C for 25 minutes and immediately chilled and stored

Smoked oysters

The meat is washed, treated with 5% brine for 5 minutes, drained, dipped in edible oil, spread in a single layer on a nylon wire mesh, drained again and loaded into a smoking chamber. The meat is held in dense smoke and maintained at a temperature of 40 o C for 30 minutes and later at 70 o C for 90 minutes. The smoked oysters are filled in cans with hot refined oil. The cans are seamed, sterilized at 115 oC for 25 minutes and immediately chilled and stored.

Oyster stew

Oyster which are too large or badly cut while shucking or those in low condition, are prepared as for canning but are chopped into small pieces and added to milk and spices.

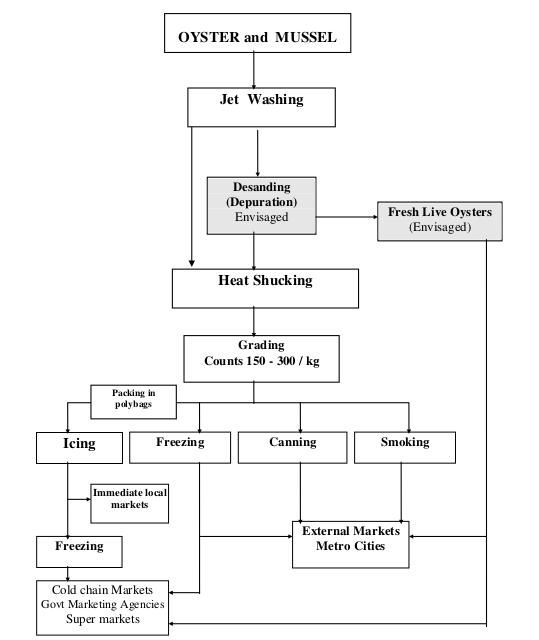

POST-HARVEST FLOWCHART

Byproducts and utilization

The two shell valves constitute about 85% of the total weight of oyster and contain 52-55% calcium oxide. They are used in the manufacture of calcium carbide, lime, fertilizers and cement. They are useful spat collectors in oyster culture. The shells are broken to pieces and used as poultry grit.

Quality of Oyster Meat and Shell

Oyster meat is relished in most nations. The proximate composition of the oyster meat and the medicinal values attributed to it are given below.

- Oyster meat consists of 52% protein, 14% glycogen and 11 % fat

- Oyster powder contains wide range of minerals and vitamins and the amino acid taurine, which has complex medical properties.

- Oyster powder has shown good results in skin care, numerous heart ailments, blood pressure, liver problems, arthritis and rheumatism, diabetes, water retention, premenstrual tension etc.

| Rack and ren method | Oyster farm Ren |

5x5 m | ||

| Fixed Cost | ||||

| 1. Fixed cost (Matrial coast) | ||||

| Item | Quantity | Rate/unit | Amount | |

| Bamboo poles (16 poles +14 horizontl poles) | 30nos | 320 | 9600 | |

| Rop (Farm costruction) 3mm | 2 kg | 250 | 500 | |

| Rope (Ren making )3mm | 6kg | 250 | 1500 | |

| Total | 11600 | |||

| 2.Recurrring Cost | ||||

| Shell | 1500 nos | 50 paise | 750 | |

| Ren making | 300 nos | 2 | 600 | |

| Farm construction | 2 labours | 850 | 1700 | |

| Installation of spat setters | 1labour | 850 | 850 | |

| Harvesting | 4 labours | 850 | 3400 | |

| Canoe hire charges | 5 days | 250 | 1250 | |

| Depuration charges | 1500 kg | 7 | 10500 | |

| Fuel charges ** | 1 cylinder | 2000 | 2000 | |

| Shucking charges ** | 105 kg | 50 | 5250 | |

| Single oyster declumping | 3000 | 1 | 3000 | |

| Total | 29300 | |||

| 3.Marketing expense | ||||

| Live oyster | 3000 | 5 | 15000 | |

| Heat hucked meat ** | 105 | 50 | 5250 | |

| Total | 20250 | |||

| Total financial outlay | ||||

| Shell on | 3000 | 20 | 60000 | |

| Shucked meat | 105 kg | 500 | 52500 | |

| Profit | ||||

| Shell on | 60000-11600-21800- 15000 = 12100 | |||

| Shucked meat | 52500-11600-29300-5250 = 6350 | |||

Some useful information for planning oyster culture in Kerala

| Ideal location | Estuaries with salinity 10 to 32 ppt |

| Duration of culture | 6 to 8 months |

| Season for culture | Post and premonsoon ( November to May) |

| Source of Seed | Natural oyster beds |

| Method of seed collection | By placing rens during post monsoon period |

| Ideal grow out structure | Rack |

| Material necessary for oyster farming | 3mm nylon rope Empty oyster shells Bamboo / casuarina poles |

| Source of funding | Subsidy given by FFDA/ADAK |

| Market | As Fresh oysters locally Or to IFP, Cochin as heat shucked meat |

| Disease problems | Till now no reports |

| For training for farmers/ officials Pl. contact - | CMFRI, Kochi. |

Last Modified : 12/11/2019

This topic deals with information related to Appen...

The Article provides information about Antioxidant...

This topic provides information about Sim Card Swa...

This topic deals with information related to Anxie...