Production of Nile Tilapia

Production of Nile Tilapia

Tilapia is a euryhaline fish which can be grown under different culture methods like the pond, cage, biofloc tank, aquaponics and re- circulatory system. It thrives well in shallow freshwater habitats. Owing to its easiness in seed production, hardy nature and adaptability to various habitats, it has got wide popularity in the world aquaculture scenario. It has the second position in global freshwater aquaculture production. It is a prolific breeder which attains sexual maturity in three months. In the natural environment, it overpopulates the habitat, resulting in stunted growth.

Tilapia is an omnivore which feeds mainly on phytoplankton, periphyton, aquatic plants, small invertebrates, benthic fauna and detritus. It can digest and assimilate plant protein. Even though tilapia mainly feeds by grazing on periphyton mats; it also feeds on entrapped suspended particles by filtration.

Tilapia breeds through-out the year as it has an asynchronous type of ovary with oocytes of different stages of development at a time. It is a nest builder, where the male establishes a territory, digs a spawning nest and guards his territory. The male then courts mature females one after other for spawning. The female spawns in the nest; picks up fertilised eggs immediately and holds it in its buccal cavity for incubation. The female carries the hatchlings there until the yolk sac is absorbed. During this time, the female eats a little or nothing. Both parents show parental care. Even if the fry are released from the buccal cavity, they will swim back when under threat.

‘National committee on the introduction of exotic aquatic species’ has approved the import of Nile tilapia (Oreochromis niloticus) to India during 2006 and its farming was approved during 2011. Nile tilapia farms shall be located in an area which is not prone to floods or in a buffer zone around a declared sanctuary or bio-reserve or other vulnerable areas to avoid escape to the open water bodies. In bio-secure farm, tilapia farming can be done using all-male or sterile improved strains or hybrid seeds, after obtaining registration and license from Department of Fisheries, following the guidelines issued. The Genetically Improved Farmed Tilapia (GIFT) and Chitralada, are advanced strains developed through the selective breeding of several generations of Nile tilapia by the World fish centre, Malaysia and Asian institute of technology, Thailand recpectively. Strains such as Big-nin, Nam-sai, Super-red and Super-black are also available.

Seed Production

Broodstock management

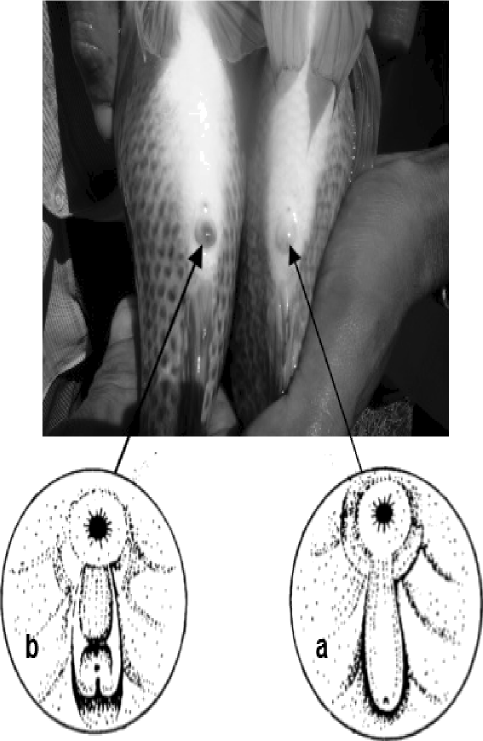

Healthy and uniform sized pair having a size range of 150-250 g without any deformities are selected as brood. In mature tilapia, sexual dimorphism is evident and is easily distinguished by visual examination of the urinogenital papillae. The adult male has a conspicuous red, blue or black colouration with white or bright dorsal and caudal fln margins, while in female colouration is less. The mature female is distinguished by its soft belly with pink coloured genital pore. The genital papilla in male tilapia has only one opening (urinogenital aperture); while the female has two openings.

The male and female broodfish are separately maintained for 2-3 weeks in hapa (3 x 3 x 1 m) at a rate of 10 no./m2 and fed three times daily at 2-3% of the body weight with floating pelleted feed having 30% protein. To prevent injuries during mating, upper lip of the male is clipped. Before removing upper lips, male is anaesthetised by using 50ppm clove oil. After mouth clipping, the wound is disinfected with 10% betadine solution.

Fig. a) Mature male b) Mature female (Courtesy. Farming of Tilapia, Hussain, 2004)

Spawning

Hormone injection is not used in tilapia to induce spawning. Brooders are stocked at a density of 1-2 no./m2 in breeding hapa (10 x 3 x 1 m) with a top covering. The ideal ratio of male to female is 1:3 or 1:2 by number. They are fed twice at 1% of the body weight with a feed having 32% protein supplemented with vitamin C, vitamin E and minerals. Even if inside the hapa, the male exhibits digging movements. After a period of courtship, the male chooses the ripest female, and the spawning and fertilisation takes place in the breeding hapa. The male then chooses another ripe female and spawning continues. A female usually spawns 6-12 times in a year with an interval of 10-30 days. If fecundity is reduced, the spent fish is separated by sex and given rest.

After lowering the water level of pond to 60 cm, the breeding hapa and buccal cavity of female is checked individually in every 7-10 days for fertilised eggs and collected carefully into a basin. The wide time gap for egg collection usually results in the production of hatched out fry, which is undesirable for hormone treatment. The ideal time for egg collection is early morning to reduce stress. The collected eggs are separated from unwanted debris, measured volumetrically (2 lakh no./l), cleaned in water and disinfected with 3 ppt brine. Usually, the fecundity is 350-600 no./fish. A small female, produces less number of eggs, which are smaller in size but spawns more frequently. The fertilised egg of tilapia is large yolky, non-adhesive and pale yellow/orange in colour. It is ovoid with 1-2 mm and 1.5-2 mm diameter.

Incubation

The fertilised eggs collected from the breeding hapa are incubated in the indoor round-bottomed jar (10-30 l capacity) which holds eggs at a rate of 1000 no./ l. It is provided with an inlet pipe from the bottom at the centre and an outlet pipe at the top. In the jar, there is a continuous water flow of 2-3 l/hr. It helps to avoid damage to chorion and subsequent loss due to attack by microbes. The hatching takes place within 2-3 days at 30 0C. Fertilised egg, after passing through several embryonic phases, develops into free-swimming fry by 4-6th day. The out-flowing water from the jar is screened through a net, which enables the collection of hatchlings. The water for incubation is screened for sediments and filtered through a slow sand filter, pressure sand filter, cartridge filter, and UV steriliser/ozoniser. The discharged water is recycled for further use, after storing in a small separate over-head- tank.

Indoor rearing and sex reversal

Soon after collecting the free-swimming larva from the incubation jar, it is graded by using 3.2 mm mesh material to remove those larvae having more than 14 mm size. The larvae are stocked at 4-10 no./l in indoor FRP tank (2 t capacity) having 60 cm height. As tilapia is a prolific breeder and the male grows twice as fast as female, all-male population is preffered for farming, for which sex reversal of female into phenotypic male is an effective solution. All male population is achieved by the administration of 17a-methyl-testosterone, a synthetic male sex hormone, through feed for 21-28 days to all young ones. A quantity of 60 mg hormone is dissolved in 200 ml ethanol (95-100%) and mixed thoroughly with 1 kg feed until it is moist. After evaporating the alcohol, the moist feed is dried under shade and stored in dark and dry condition, as the hormone breaks down when exposed to sunlight or high temperature.

The hormone fortified micro-particulate feed of less than 500 qm size having 40-45% protein is continuously fed to the young ones of 1- 28 dph. The initial daily feeding rate is 30% of the body weight, which is gradually reduced to 20%. The fry attains an average size of 0.4 g by 28 dph. The success rate of sex reversal is usually more than 95%. The water from the hormone-treated fish tank should not be discharged-out without proper effluent treatment.

Rearing of fry

After preparing the nursery pond as explained for the major carps, the hormone-treated fry is reared in outdoor tank at l000-2500/m2 for 30-40 days to attain a size of 1-3 g. It is fed 3-4 times daily with a micro-particulate feed having 40-45% protein of less than 500 micrometer size at 20% of the body weight initially and thereafter 500-800 micrometer size at 10% of the body weight. Daily 10-20% of the water is replaced.

Packing and transportation

The method followed is similar to that explained for major the carps.

Farming in Cage

The water bodies that cannot be drained or seined, which are not suitable for pond aquaculture can be used for cage farming of fish. Cage farming facilitates easy and flexible management practices which include (i) close observation of fish for feeding response, growth and health, (ii) simultaneous keeping of different age groups in various cages for multiple harvest and continuous operation, (iii) possibility of demand harvest, and (iv) low harvesting expenses. The disadvantages of cage farming are that there is complete dependence on artificial diet and more risk of loss due to poor water quality, poaching and damage to cage net by predators or adverse climate.

Selection of site

Potential resources suitable for cage farming of Nile tilapia are freshwater bodies which hold a huge volume of water and non-drainable like reservoirs, lakes, quarries, etc. The site should not have any threat from strong wind, current and wave action. Transparency of water body may be 30-40 cm with a pH of 7 to 8. Farming of Nile tilapia in cage is permitted in reservoirs or any other open water bodies, only if tilapia already existed in that habitat.

Cage design

The dimensions and construction materials of cage vary widely with location. Waterbody with a minimum water depth of 4 m is suitable for installing floating GI cages. It consists of rectangular floating platform with 460 x 360 cm outer frame and 400 x 300 cm inner frame made of GI pipe of 1-1.5 inch diameter and 1.5 mm thickness, fabricated and held together with connecting rods and clamps. A handrail of 75 cm height is provided with the inner frame. The outer HDPE cage net of 460 x 360 x 280 cm size is tied with the outer frame, and the inner HDPE cage net of 400 x 300 x 325 cm size is hanged from the top of the handrail. Even though the depth of inner cage net is 325 cm, effective water depth is limited to 250 cm (75 cm freeboard up to the height of handrail). Initially, the mesh size and twine thickness of outer cage net are 18 mm and 1 mm respectively. Later it is enhanced to 36 mm mesh size and 2 mm twine thickness. The inner cage net is of 10 mm mesh size with 0.5 mm twine thickness followed by 18 mm mesh size with 1 mm twine thickness and after that 28 mm mesh size with 1.5 mm twine thickness. Ballasting with GI rod (1.5-2 cm thickness) having the dimension of 380 x 280 cm is done to ensure cuboid shape of the cage.

The cage raft is fabricated on a flat concrete floor or evenly levelled shore to achieve perfect alignment and better joining of pipes. It is better to fabricate the cage raft near to the shore for easy launching. The fabricated cages are towed to the pre-determined location and installed securely using multi-point mooring system with the help of synthetic ropes, sealed hollow floating barrels and anchors. Empty HDPE barrels of 6-8 numbers of 200 l capacity are used as floats, and concrete blocks are mostly used as anchors. A bird protection net of 10 cm mesh size is used as top cover. Different cages are set in open waters in battery alignment.

Regarding reservoir, large HDPE floating cage of 100 m3 (500 x 500 x 400 cm effective inner dimension) is installed in the protected area where the water depth is not less than 7 m so that there will be 3 m gap from the bottom of the cage to the bottom of the waterbody for facilitating sufficient room for water circulation. The components of the cage unit are floating frame, cage net, bird protection net, anchor and a workmen shed. The inner and outer cage net is hung from a floating platform made of HDPE block. The floating platform have a walkway for working personnel. The cage unit may have an outer protective net to prevent the entry of animal predators in the reservoir. The cage is anchored with strong ropes from diagonally opposite sides of the cage structure. Ballast pipe as per cage size is provided in each frame for maintaining the shape intact.

The arrangement of cage unit is done in such a way that at least one side of a cage has access to open water which is done by arranging two rows of the cage in a line separated by a walkway. On one side of the unit, a workmen shed is built to store the feed, net, twine, rope, medicine, etc. and also for the security personnel. Adequate lighting, with solar power system is provided. A small canoe is required to transport personnel and material to the cage site.

Stocking

The seeds procured from a Government approved hatchery are stocked in inner rearing cages of 10 mm mesh size at a stocking density of 125 no./m3 after acclimatisation and are reared for 6 weeks. As the fish attains a size of 35 g, it is graded by size and stocked in inner grow-out cages with 18 mm mesh size at a stocking density of 60-120 no./m3 based on water quality parameters. As the fish attains a size of 100 g, it is graded by size again and stocked in inner grow-out cages with 28 mm mesh size. Grading is done by using nets of varying mesh size. Acrylic or metallic graders are also used.

Feeding

In the cage, the fish is fed with a formulated floating pelleted feed. Sampling is done weekly to assess growth rate and the feeding rate is adjusted accordingly. The feed is usually given twice daily during the dry season and four times in the rainy season. The protein content and size of feed and daily feeding rate are determined based on Table-

Feed requirement

| ABW (g) | Protein content (%) | Feed size (mm) | Daily feeding rate (% of ABW) |

| 3-5 | 34 | 0.8 | 10 |

| 2-25 | 32 | 1.2 | 8 |

| 25-100 | 28 | 1.8 | 6 |

| 100-250 | 24 | 3.0 | 4 |

| 250-400 | 24 | 4.0 | 3 |

| >400 | 24 | 6.0 | 2 |

Care and maintenance

Constant care is given to the cage installed in open waters as it is often prone to poaching. During adverse weather condition, anchor rope should be checked. Once a week, the cage net is cleaned with soft brush to ensure proper water exchange. The cage net is examined frequently to check for any damages which can lead to intrusion of predators and crop loss.

The health of fish is examined fortnightly by taking it out using hand net. As tilapia is a hardy fish, the occurrence of disease is less. Water quality parameters are also checked regularly. Once in a month, fish growth is monitored to determine the feeding rate, followed by grading and thinning.

| DOC | Size of fish (g) |

| On stocking | 3 |

| 45 | 10 |

| 90 | 100 |

| 120 | 200 |

| 140 | 300 |

| 160 | 400 |

| 180 | 500 |

Harvesting

It depends on factors like the preferred market size and seasonal demand. If there is no uniformity in size, the stock that attains marketable size is harvested partially from 5th month onwards, and the remaining fish are allowed to grow further. Harvesting is done by lifting the cage and scooping-out the fish by hand net. Feeding is stopped one day before harvesting to allow the fish to empty its gut. With optimum feeding rate, Nile tilapia grows to attain 500 g within 5-6 months. A production of 25-50 kg/m3 can be expected from one crop with a survival rate about 85%. It is possible to raise two crops in a year.

Aquaponics System

The aquaponics system is operated for high fish production from less area. Here, fish farming is integrated with the vegetable crop, by re- circulating the used water from the fish tank and bio-degrading the metabolite like ammonia into nitrate, which is utilised by plants. Simultaneous production of fish and vegetables using the same resources is the visible output of this practice. When compared to extensive pond farming, the requirement of water is merely 4% for unit production in this system.

Design

Circular, rectangular, square or oval-shaped tanks of different size are being used; however, 40 m3 (5 x 5 x 1.6 m) fish tank with 120 m2 vegetable beds is the most common. After excavating soil in the required dimension, a protective wall of one feet height is constructed by using hollow bricks at the top edge of the pit. At the bottom of the pit, a layer of cushioning material like hay is provided. After applying insecticide inside the pit, it is lined with polythene sheet of 500 gsm. In low-lying area where high ground water column exists, reinforcement with hollow bricks is given at the bottom and sides of the pit.

The level of DO, TAN and pH in a 40 m3 fish tank is maintained at the optimum level through continuous water re-circulation with the help of two submersible water pumps (80-120 W) alternately and continuous aeration using two air pumps (90-140 W). An automatic generator (1 KV) or inverter is required as electric power back-up. Bio-fencing is given by covering the roof with UV resistant sheet and sides with orchid netting.

The water from the fish pond is pumped-out into the settlement tank and allowed to pass through a mechanical filter to separate solid waste. Then the water is passed through a bio-filter where the toxic nitrogenous waste like ammonia is converted into nitrite and nitrate by Nitrosomonas and Nitrobacter respectively. Then the water is allowed to flow intermittently using siphons over the gravel (3/4 inch size) arranged in the vegetable bed (30 cm height) where the nitrate contained in the water is utilised by the plants, and the water is again supplied back to the fish pond. The vegetable bed also acts as both a mechanical and a bio-filter. Vegetables like cabbage, cauliflower, amaranthus, mint, chilli, coriander, brinjal, eggplant, spinach and tomato are cultivated in the vegetable grow bed.

Stocking

The seed of 4-6 cm is stocked after acclimatisation. The maximum allowable stocking density is 150 no./m3. However, a stocking density of 100 no./m3 is preferred for better growth rate and survival.

Feeding

Tilapia is fed with a formulated floating pelleted feed for 3-4 times per day. The protein content and size of feed and rate of feeding are determined based on Table - 1

Water quality parameters

Water quality parameters such as DO, temperature, pH and transparency are monitored on daily basis. The level of TAN is checked at weekly intervals or periods of reduced feed consumption. Optimum water quality parameters are given below.

Temperature : 24-30°C DO : >5 ppm

pH : 6.5-7.5 TAN : <0.1 ppm

Alkalinity : 80-120 ppm NO2°N : <0.01 ppm

Hardness : 60-140 ppm NO3-N : 5-150 ppm

CO2 : <40 ppm

Care and maintenance

The possibility of disease in RAS is limited. However, poor water quality management and increased handling stress may lead to diseases. At frequent intervals, the working of mechanical and bio-filter is examined, and then the filters, pumps and siphons are cleaned. Bio-filter is stirred or agitated occasionally to prevent clogging.

Harvesting

The fish grows to a harvestable size of 500 g within 5-6 months. However, partial harvesting is done from a size of 400 g onwards. Production of 40 kg/m3 is obtained with a survival rate of 90%. Two crops can be raised in a year.

Biofloc Aquaculture System

Biofloc aquaculture system is one of the most promising and affordable intensive aquaculture systems, which is ecologically, nutritionally and economically sustainable. The fundamental principle behind the biofloc system is the process of converting inorganic nitrogen into protein by the addition of an external carbon source. This system reduces the requirement of water and feed and thereby production cost. It also offers scope for high stocking density, improved productivity, bio-security and maximum nutrient utilisation though it requires good technical skill and high electric energy input. In biofloc aquaculture system, different strains of tilapia are found to be performing well in terms of yield and nutrient utilisation. Tilapia tolerates high stocking density and high amount of suspended solids and survives well under a zero water exchange-based system. For biofloc tilapia farming, registration and license should be obtained under Kerala Inland Fisheries and Aquaculture Act, 2010.

It is estimated that 75% of the nitrogen in the feed remains in the water as uneaten feed and through excretion of nitrogenous metabolites generated by fish which adds-up ammonia and nitrite in water which are toxic to fish. In Biofloc system, these nitrogenous compounds are assimilated by the consortia of heterotrophic bacteria under controlled conditions, which further form protein rich microbial diet to fish. The main constituents within the biofloc are the heterogeneous aggregates of extracellular polymeric substances with suspended organic particles to form a matrix that encapsulates the heterotrophic microorganisms of more than 2000 species which predominantly includes diatoms, macro- algae, bacteria and invertebrates. Usually, the density of biofloc will be 106-109 no./cm3, and floc size varies from 100-250 um depending on the extent of aeration. The microbial population is reported to have a protein content of 32-38% and can supplement up to 5-10% of the protein requirement of fish. So the feed protein requirement and the cost of feeding can be considerably reduced.

Biofloc unit design

In this system, a circular tank of 4-6 m diameter with 1.2 m peripheral height with a slope (25:1) towards the centre is ideal. The tank is placed on a levelled hard earthen or cemented platform. The tank is constructed with epoxy coated Galvanized Iron (GI) wire mesh of 4-5 mm thickness with a mesh size of 1-2 inch supported vertically with rectangular epoxy coated GI pipe (0.75 inch thickness and 18 gauge) at a distance of 3 m and horizontally with two circular ribs of steel rod having 8 mm thickness. In places having the possibility of rodent attack, the tank is constructed by using epoxy coated GI sheet of 2800 gsm (g/m2) thickness supported vertically with rectangular epoxy coated GI pipe (0.75-inch thickness and 16 gauge) at a distance of 50 cm and horizontally with three circular ribs of aluminium beading with 1 inch width and 3 mm thickness. The horizontal ribs are arranged in such a way that one is placed at the inner top edge, the second one at the outer top edge and the third one at the outer middle. Inside the framework, cushioning material like polyfoam mat of 4-6 mm is placed at the bottom and all around the sides to protect the sheet from tearing and temperature fluctuations. Above the polyfoam mat, a polythene sheet (PVC coated HDPE/ nylon) having 1.5 m height with 550 gsm thickness is placed. Out of the 1.5 m height of polythene sheet, remaining 30 cm after covering the total height of the tank, is folded outward through the top surface of the tank and is tied with the outer, middle aluminium beading of the tank by using synthetic rope. The tank has a drainage pipe of 2-3 inch diameter at the bottom centre towards the side for ensuring sludge removal from the tank. A bush system arrangement with perforated pipe is provided inside the tank with the drain pipe. The drain has an outer opening at a height of 30 cm to discharge sludge and another opening to remove overflow water above 1 m height. The tank is provided with shade net roof to control sunlight. Additionally, it can also have a polyvinyl sheet above the shade net roof to prevent rainwater falling into the culture unit.

Each tank of 20 m3 is provided with two air pumps of 120 l/min capacity each which requires less voltage for maintaining the DO and TAN at optimum level. It is advisable to connect the air pump or blowers in such a way that it takes care of any uncertainity related to damage of one blower for maintaining required aeration. The aeration unit has 8 independent points made with aeroxy tube (algal resistant) in the shape of rings (15 cm diameter) at the bottom. The air pump is connected to these aeroxy tube rings through PVC pipes (2 inch) followed by PVC reducers and garden hose (1/2 inch diameter). At the periphery 4 more air points (rings) is provided in the water column 30 cm above the bottom, in which non-clogged air stones are used instead of conventional air stones. The air supply through each point is maintained as 5 l/minute using regulators. Care should be taken to place the air pumps above the water level. No external filtration is provided with the system.

Usually, the operation of biofloc units are maintained on zero water exchange mode except for the replenishment of water which is done using a water pump (80-120 W) to compensate the water lost through sludge removal and evaporation. Power failure of more than l hr often leads to mass mortality of stock. Hence, there must be an automatic electric generator or inverter of sufficient capacity to ensure uninterrupted supply of electric power. The tanks are arranged in rows for easy operation of aeration, filling and drainage of water.

Due to the increased suspended solids concentration, earthen pond devoid of linning with polythene sheet is not suitable for biofloc culture system. Any polythene lined earthen pond up to 0.1 ha or cement tank with a central drain facility having a volume of 12-30 m3 with suitable aeration arrangements is ideal. Cemented tank with side drain can also be considered. The pond has 1.2 m height at the periphery with a gradual bottom slope towards the centre so that it becomes 1.5 m height. Besides, there is a sludge collection pit of 60 x 60 x 30 cm at the centre, and it is connected with a drainage pipe. The pond is constructed by excavating the soil and has a protective bund of 60 cm height at the top edge. It is lined with polythene sheet of 550 gsm after applying insecticide and laying cushioning material. Waterlogged area should be avoided.

Two single-phase air pumps or air blower (roots type) of 1 hp capacity fitted with 16 pieces of aeroxy tube of half inch inner diameter (algal resistant) in the shape of rings of 30 cm diameter is required at the bottom for each 2 t fish for providing aeration continuously, to make the biofloc under suspension and also for maintaining the DO and TAN at the optimum level. Bio-fencing is given by covering the sides with orchid netting. To ensure better protection from rainwater and to reduce sunlight PVC sheet may be provided above the shade net.

Water source

The tank is filled up to a height of 1 m with good quality water preferably from a well. If water from an open water source is used, it is chlorinated using sodium hypochlorite (35-50 ppm available chlorine) followed by de-chlorination after 24 hours of chlorination by vigorous aeration for 24-48 hours or by treatment with sodium thiosulphate. Check all the water quality parameters of source water in a certified laboratory. The parameters such as pH, alkalinity etc. need to be monitored. The heterotrophic bacterial growth is faster in preferred alkalinity of 80-100 ppm. If alkalinity is less, the required correction can be carried out by adding sodium bicarbonate @ 40 mg/l or dolomite @ 100 mg/l to the water.

Biofloc formation

Biofloc must be made ready before stocking, and for that, a suitable inoculum is developed and inoculated into the culture tank. If carbon source such as molasses, jaggery or rice bran is used for inoculum development, it needs to be fermented with yeast in the ratio of 100:1 with aeration for 24 hours before adding it into inoculum. For a 20 m3 tank, 200 1 inoculum is sufficient which is prepared in a covered barrel (250 1 capacity having a wide mouth of not less than 50 cm diameter) under vigorous aeration using 3-4 air points.

After filling 200 l water in the barrel, add 4 kg of soil collected from an existing pond which has no history of any disease and the soil should have sufficient clay and silt portion rather than sand. 10-20 litres of slurry from adjacent biofloc unit can also be used for inoculum preparation. The soil can be partially dried under the shade and used as a seeding source for the bio-flocculating organisms and natural microbes. Complete drying or drying under direct sunlight should not be done as it destroys microbes in the soil. Along with the dried soil, add ammonium sulphate @ 10 mg/1 (2 gm for 200 1) and fermented jaggery @ 200 mg/1 (40 gm for 200 1) in to the barrel. Aerate the inoculum vigorously for 24-36 hours in the barrel. The inoculum is added to the tank @ 1 l per 100 l of culture water and aerated well. For inoculum preparation, only nitrogen fertilizer should be used and fish feed shall not be used.

The second day after inoculating the tank, it is added with nitrogen fertiliser (ammonium sulphate @ 0.5-3 mg/l). On the next day, fermented jaggery (fermented with yeast for 24 hours) is added as carbon source to maintain the prescribed Carbon: Nitrogen (C/N) ratio at 15:1 to 20:1 during initial days. During subsequent days, nitrogen fertiliser and the carbon source is added at a frequency of 2-3 days interval according to TAN level. When TAN exceeds 2 mg/l, additional carbon source is added with the above C/N ratio. High C/N ratio induces the assimilation of nitrogenous by-product by heterotrophic bacteria and hence ammonia control in culture tank can be achieved.

At first, autotrophs develop which will lead to green colour water followed by a transition phase where foam formation happens. The water will gradually turn into brown colour. The microorganisms develop naturally within 7 days, and thousands of heterotrophic organisms develop within 10-14 days.

Stocking

The biofloc develops and reaches 5-10 ml/l within 10-14 days, and the system becomes ready for stocking. The floc volume is measured with the help of Imhoff cone after settling the water in it for 20-40 minutes, and the floc volume is expressed as ml/l. After PCR screening and proper acclimatisation, tilapia seed of 2-5 g size is stocked @ 50- 100/m3 in tank.

Feeding

Tilapia is fed 3-4 times daily with formulated floating pelleted feed in equal quantities as per below Table. The feed is stored in airtight containers and kept in a moisture free environment to avoid any fungal infection. As the fish consume biofloc, the quantity of feed is reduced by 20-30%. The size and protein content of feed and daily feeding rate are given in below Table, but it should be adjusted according to biofloc density. Biofloc system being efficient in providing in-situ protein to the fish with the FCR of 1.1-1.2

Feed requirement

| ABW (g) | Protein content (%) | Feed size (mm) | Daily feeding rate (% of ABW) |

| 3-5 | 32 | 0.8 | 6 |

| 5-25 | 28 | 1.2 | 4 |

| 25-100 | 28 | 1.8 | 3 |

| 100-250 | 24 | 3.0 | 3 |

| 250-400 | 24 | 4.0 | 2 |

| >400 | 20 | 6.0 | 2 |

If differential growth is observed, feeds of prescribed size for both small fish and large fish should be given together, preferably large fishes to be fed first followed by the small ones. In order to check aflatoxin poisoning, colour and smell of the feed should be monitored for each individual sack opened afresh.

Biofloc maintenance

Continuous and vigorous aeration is mandatory to keep the biofloc in suspension. The quantification of floc volume gives a reference to decide the quantity of sludge drainage. As the fish grows, the floc volume also increases in proportion to feeding. If floc volume exceeds 40 ml/1, the excess floc is discarded out through the drainage pipe with the help of a valve and an equal quantity of water is replenished. In the case of large units of more than 100 m', there should be separate provisions for handling and treating the sludge which is discharged from the unit. The sludge can be allowed to settle, and the supernatant water can be pumped back to the culture tanks. The sludge can be further dried and used as a fertilizer for any crop.

The quantity of nitrogen generated in water is estimated by multiplying the quantity of feed given daily with a constant of 12x10-1 and percentage of protein content in the feed. The quantity of carbon source is determined by multiplying 10 with the quantity of nitrogen generated in water and dividing by the percentage of carbon content in the source. (If the fish is fed with 1 kg feed having 28% protein content, the nitrogenous metabolites contain 33.6 g N. As the molasses and jaggery (industrial quality) contain 50% carbon, its requirement is 672 g/kg feed). Moreover, it is advised to add vitamin-mineral mixture and probiotics once in a month during various stages of culture for enhanced production.

Water quality parameters like TAN need to be measured to plan the management protocol. TAN measurement is done once in 3 days during the initial 1 month and can be done once in 6 days later-on. Initial maintenance of C/N ratio is 15:1 to 20:1. It means, to remove 1 mg/l of TAN, the required carbon source is 15-20 mg/l. If the carbon sources are conventional (Jaggery, tapioca, etc.), they need to be added in double the amount should be added : ie, 30-40 mg/l. As the culture progresses, the C/N ratio is maintained at 6:1 to 10:1. Whatever be the carbon source, it should be free from any pathogens. Before addition to the culture pond, carbon sources like molasses, jaggery and rice bran require fermentation by yeast in 100:1 ratio.

Water quality parameters

The water quality parameters such as DO, temperature, pH, TAN, NO2. NO3. TSS and alkalinity are monitored on a daily basis initially and subsequently once in every three days or during reduced feed consumption. Collect one litre of water from two opposite points at a depth of 15 cm from the water column in between 10-11 a.m. for estimating water quality parameters. Optimum water quality parameters are given below.

Temperature : 28-30°C DO : >4 ppm

pH : 7-8.5 TAN : <1 ppm

Alkalinity : 100-120 ppm NO2-N : <l ppm

Hardness : 60-140 ppm TSS : <500 ppm

In order to control alkalinity, either dolomite or sodium bicarbonate should be used. For low pH and high alkalinity dolomite wrapped in small bags can be deposited.

Care and maintenance

The fish is collected using scoop net and examined for health conditions. Morphometric measurements of 5-10 fishes are taken randomly using an electronic balance and stainless steel scale to estimate average body weight and length of fish and the quantity of feed is regulated accordingly. The microorganisms associated with biofloc thrive on metabolic waste, and thus the system becomes bio-secured. Hence, there is no water quality deterioration and entry of pathogen. If PCR screened seed is selected, the possibility of viral disease is limited. Never use a feed of more than l kg/m3/day; in other words, the quantity of nitrogenous metabolites generated from the fish should not exceed 672 g/m3/day. However, if the biofloc level exceeds the limit of 35 ml/l, feeding and addition of carbon source are reduced or even stopped for a few days till the system stabilises.

After stocking, the TAN level will increase steadily, which should be managed with the regular addition of carbon source in a frequency of 3-4 days. Addition of excess carbon source leads to more solid accumulation and gill clogging of fish. Failure of proper aeration leads to crashing of the system. Inadequate addition of carbon source leads to the transformation of heterotrophic process to autotrophic, which slows down nitrification and intensive rearing may not be successful in such a system. More than I kg of carbon source should not be added at a time to the culture unit. As a thumb rule carbon source given should be half

of the total feed quantity given for the 1st 3 weeks. In biofloc units

culturing GIFT, salt addition is not required. If alkalinity is low, supernatant solution of dolomite can be added @ 100 mg/l. As far as possible, the use of commercial inoculum should be avoided.

Harvesting

The fish grows to a harvestable size of 350-500 g within 5-6 months. However, partial harvesting is done from a size of 350 g onwards. Production of 25-40 kg/m3 is obtained with a survival rate of 80-90%. Being an exotic fish, Nile tilapia should not be marketed in live condition. It is marketed in fresh or iced condition, and there is a good demand for tilapia fillet and hence can explore the value addition in marketing. The advantage of a tank based system is that crop can be grown in different tanks at different time to ensure year-round continuous supply of fish which helps to overcome the fluctuating market demand and price. Two crops can be raised in a year.

Farming in Pond

Site selection & pond construction

Nile tilapia farming in the earthen pond is more economical as it utilises the available natural feed organisms effectively. Tilapia farming is practised in the rectangular earthen pond having minimum water spread area of 0.05 ha with 1-1.5 m water depth. The slope of the pond dyke is 2:1, as tilapia digs soil which may easily weaken the bund. Bund height is high enough to avoid fish from escaping. The pond is provided with sufficient biosecurity measures including top cover with a net having a mesh size of 50 mm and side fencing with a stiff net of 26 mm.

The discharge water from the pond, if released into open water bodies, is screened with appropriate mesh size and treated, to prevent the escape of fish, eggs or fry into natural water bodies. Other aspects are the same as those of major carps.

Preparation of pond

The pond preparation steps such as de-siltation, bund strengthening, installation of water inlet and outlet, draining, drying, tilling, eradication of aquatic weeds, liming and manuring is followed similar to that of major carps. Use of bleaching powder is ideal for the removal of pathogen, predator and weed fish.

Water quality parameters

Temperature : 24-36°C DO : >4 ppm

Transparency : 30-40 cm TAN : <0.2 ppm

pH : 100-120 ppm NO3-N : 0.04-0.08 ppm

Alkalinity : 60-140 ppm P2O5 : 0.04-0.1 ppm

Stocking

After the development of plankton, properly acclimatised seeds is stocked in cage, happa or pen installed in the same pond. The stocking density in the grow-out pond is 3-5 no./m2.

Feeding

Nile tilapia consumes almost all kinds of commercial diet from the fry stage onwards. Formulated floating pelleted feed having 24-34% protein is given as supplementary feed at a rate of 6% of the bodyweight initially and subsequently reduced to 1% during the last month. Feed is given twice daily, in the morning and evening. The details of feed requirement, feed size and protein requirement is given in above Table, but it may be regulated after examining the plankton production, health condition and growth rate of fish at frequent interval.

Care and maintenance

5-10% of the water in pond is replaced with fresh water fortnightly. Paddle-wheel-aerators (4 hp/ha) are installed to maintain water quality.

Intermittent application of agriculture lime, manure and other monitoring procedures are similar to that of major carps.

Harvesting

Feeding is stopped two days prior to harvest. Partial harvesting of large fish is usually done from 5th month onwards with a cast net. During complete harvest, the pond is dragged 3-4 times. A complete harvest is not possible by dragging alone as tilapia can escape from dragnet. Hence, the pond is drained to collect the remaining fish. After harvest, the pond is dried and chlorinated (35 ppm) to avoid the carry over of tilapia fry to the next production cycle. Harvested live fish is kept in clean running water for a day to reduce off-flavour (purging). In semi-intensive culture system, within a culture period of 5-6 months, fish production of 12 t is expected from one crop with a survival rate of 80%. By this period, Nile tilapia attains the size of 500 g.

Last Modified : 12/29/2022

This topic provides information about Trout Cultur...

Provides summary of District Agriculture Plan Wash...

ICAR-Central Institute of Fisheries Technology COV...

This topic provides information about Marine Fin F...