Guar Gum

Guar Gum

Guar gum is the gum derived from seeds of the guar plant (Cyamopsis tetragonoloba).

Local name: Guar gum

Plant Source: Cyamopsis tetragonolobus (L.) Taub

Family: Fabaceae

Distribution:The guar or cluster bean is an agricultural crop grown in arid zones of West and North-West India, Pakistan, Sudan and parts of USA. India grows over 850,000 tons, or 80% of the total guar produced all over the world. 75% of the guar gum or derivatives produced in India are exported, mainly to USA and to European countries.

Rajasthan in western lndia is the major guar producing state, accounting for 70% of the production. Guar is also grown in Gujarat, Haryana, Punjab and in some pars of Uttar Pradesh and Madhya Pradesh.

Production in India:

Guar seeds - 8,50,000 tons per annum (approx.)

Guar gurn - 2,10,000 tons per annum

Other producing countries: Pakistan, Sudan, Australia and USA.

Cultivation of Guar

Guar is being grown in India since ancient time. The tender green guar is an important source of nutrition to animals and humans and is consumed as a vegetable and cattle feed. Guar is a drought-tolerant plant which needs moderate legume crop, which grows best in sandy soils and needs Moderate ,intermittent rainfall with lots of sunshine. below the soil surface. lts roots develop well in lateral direction also. Some of the varieties ave small hair on all parts of plant whereas some have glabrous (smooth, no hairs) leaves,stems and pods. The leaves are alternate trifoliate and are borne on long petioles.Plants have single stem, fine branching or basal branching and grow as high as 45-100 cm. The flowers are small, and white. The pods are oblong and 5 to 10 cm in length. Pods normally contain 5 to 12 seeds of oval or cube shape of variable size and color.

below the soil surface. lts roots develop well in lateral direction also. Some of the varieties ave small hair on all parts of plant whereas some have glabrous (smooth, no hairs) leaves,stems and pods. The leaves are alternate trifoliate and are borne on long petioles.Plants have single stem, fine branching or basal branching and grow as high as 45-100 cm. The flowers are small, and white. The pods are oblong and 5 to 10 cm in length. Pods normally contain 5 to 12 seeds of oval or cube shape of variable size and color.

For optimum plant growth, guar requires rain before planting and again to induce maturation of the seeds. Too much precipitation can cause the plant to become more "leafy" thereby reducing the number of pods and/or the number of seeds per pod that affects the size and yield of seeds.

Period of cultivation and harvesting

Guar is a rain fed crop and is generally sown after the monsoon rainfall between the second half of July and early August. It is harvested from late October till November.

Yield

The average yield of guar seed in India is around 500-700 kg/ha.

Processing and Value Addition

Guar is a pod-bearing plant with six to nine seeds per pod. Each seed or bean is composed of hull, endosperm and germ parts,typically in a weight proportion of l5%, 40% and 45% respectively. The germ portion is predominantly protein, and the endosperm predominantly guar galactomannan or guar gum. Germ and hull are used as animal feed after proper treatment.

endosperm and germ parts,typically in a weight proportion of l5%, 40% and 45% respectively. The germ portion is predominantly protein, and the endosperm predominantly guar galactomannan or guar gum. Germ and hull are used as animal feed after proper treatment.

During processing, all these three constituents are separated. The guar gum powder is obtained after removing the hull and germ from the seed and grinding the endosperm into fine powder. The endosperm ranges from 32-42 percent depending on the variety and maturity of the crop. So, the main unit operations involved in processing of guar seeds are cleaning, grading,dehusking,splitting and separation of endosperm, grinding and purification of powder. On arrival at the processing plant,seeds are screened for removal of dirt, stones, sand, metal debris,chaffs and broken seeds.Standard seed cleaning vibrators, electromagnets, and shifter are used for cleaning.

Dehulling and splitting of the two processes seed is done by i.e. dry grinding and wet grinding. In some of the industries, charring of the hull is done by flame treatment and then separation of husk is done. Recovery in wet processing method is 8 to 10% higher than in dry processing. However, the quality of the gum is not good. Hence, dry processing or charring the seed is used in most of the industries. Bun mills, pin mills and modified hammer mills are usually used for splitting of guar seeds into two halves so as to separate the germ and endosperm. The splits are then heated in kilns and passed through the dehusking machines usually consisting of a two-tired chamber, each with a rotating saw-toothed blade. Splits stripped of their hull pass to sifters that separates the clean endosperm pieces on a 20-mesh screen.

Guar gum powder is produced from by grinding in attrition mills, hammer mills, ultra fine endosperm splits simply grinders or other size reduction equipment, However, guar gum with the best thickening power and fastest hydration rate is produced when the splits are first soaked in water and then flaked, extruded or ground.

The guar gum powder is usually modified with chemicals to give them new properties for broader applications. For industrial applications, many guar gum products are formulated with additives that control the rate of hydration, enzyme resistance, dispercibility, dry flow, or other special properties. The most common commercial derivatives of guar gum are hydroxypropylguar, carboxymethylguar and 2-hydrixy-3 (trimethylammonium chloride) propylguar.

Storage and handling: Guar gum powders are generally packed in sound clean, dry and unused polythene bags placed inside gunny bags or multiply craft paper sacks

Guar gum powders and its derivatives are stable in dry form. It has a long storage life in its dry form provided that it is warehoused properly. The properties of guar gum remain unchanged for 12-18 months. However, when exposed to humid condition, guar gum absorbs moisture which results in microbiological degradation, fermentation and lumping of the powder and the properties of the gum is adversely affected. Hence, guar gum should be packed in moisture proof packets/containers and stored in a cool dry place away from heat and sunlight. Ir is advised to consume the guar gum within a reasonable time period once the bag is opened. The shelf life of guar gum may be extended by adding suitable preservatives.

Quality control : The commercially available guar gum powder must meet the standards of United States FCA and European Union Specifications (Table 2 and 3). This standard is mainly for food uses.

Properties

- Guar gum is a natural high molecular weight polysaccharide composed of galactose and mannose units combined through glycosidic linkages.

- Colour of guar gum powders varies from white to cream -colour

- Guar gum powder and solution is odorless and has a bland taste

- Guar gum powder dissolves rapidly in cold as well as in hot water. It is insoluble in organic solvents

- Guar gum powder is slightly acidic in nature and pH of 1% solution ranges from 5.4 to7.7.

- lt has good film forming property

- Guar gum is a very good thickening agent with high water binding capacity

- Guar gum hydrates rapidly in cold water and Produce highly viscous solution

- Guar gum is compatible with many other hydrocolloids used in food formulations

- Versatility due to number of free hydroxy groups to make derivatives for specific applications

Table 2 - US standard specifications of guar gum power for food uses

| S.No | Properties | Maximum permissible limit |

|---|---|---|

| 1 | Total Ash | 2.5 |

| 2 | Moisture | 12.0% |

| 3 | Acid insoluble residue | 4.0% |

| 4 | Galactomannan | 80.0% |

| 5 | Protein | 4.6% |

| 6 | Arsenic | 3 ppm |

| 7 | Lead | 10 ppm |

| 8 | Zinc | 25 ppm |

| 9 | copper | 50 ppm |

| 10 | pH | 5.5-7.0 |

Table 3 - Maximum permissible microbial content

| S.No | Properties | Maximum permissible limit |

|---|---|---|

| 1 | Aerobic plate count | 10,000 per gram |

| 2 | Yeast and Mold | 500 per/gram |

| 3 | Coliform | 50 per gram |

| 4 | E-coli and salmonella | Nil |

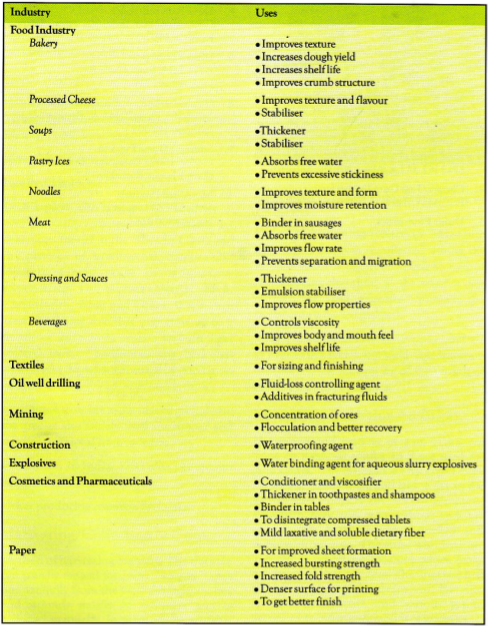

Industrial Applications

The largest market for guar gum is in the food industry, where it is used as a thickener and binder of free water. Guar gum also finds extensive use in many industrial applications. The various applications of guar gum in different industries are given in the following Table.

Last Modified : 3/1/2020

This topic provides information related to cultiva...

This topic provides information about the cultivat...

This topic provides information related to cultiva...

This topic provides information related to cultiva...