Low-cost Ginger storage structure

Low-cost Ginger storage structure

Need for ginger storage in North East India

Ginger is the major rhizomatous crop grown by almost every farmer of the north-eastern region. Ginger is sown in NEH region during April & May. Crop matures in 8-9 months and harvesting is done during December and January. Depending upon the prevailing demand, the green ginger (tender rhizome) is also harvested after 6 months of sowing for preservation, pickling and consumption. The mature crop is harvested and rhizome material is separated from the marketable ginger. Subsequently farmers have to dispose of the ginger immediately into the market and accept the lowest rate of their produce because at the time of harvest, the farmers do not get remunerative price. Farmers prefer to store the ginger and its propagative material. The rhizomes storage is essential for the next cultivation.

Traditional Method of Rhizome Storage

Traditional storing of rhizome is done in many ways, but the prevailing methods in NE region are (i) in-situ storage and (ii) pit storage.

In-situ storage:

Since harvesting falls in the month of December and January, farmers traditionally do not go immediately for the next cultivation because their farms are unirrigated. They harvest according to the market demand and consumption and allow the rest of rhizomes to remain unearthed in the field. These are dug out at the time of the next sowing. The pros and cons of this practice are;

- To save the labour for harvesting, handling and storing

- To save the expenditure on additional storage structure

- About 50% crop spoil due to over maturing, rotting or disease susceptibility

- Rhizomes start sprouting in course of time.

Pit storage:

A circular or rectangular pit is dug according to the requirement. A thin layer of straw is first spread over the bottom of pit and rhizomes are placed into this layer in the pit up to a little less than the ground level. Again a thin layer of straw covers the rhizomes. The final covering is done with the soil to the ground level. It is opened before the next sowing season and healthy rhizomes are sown.

In this method, the rhizomes get spoiled in two ways;

a) around 25-30% rhizomes rot in the pit itself and

b) about 10-15% rhizomes sprout in the pit are rendered useless for sowing.

This loss is incurred because;

a) pits are kept outside and underground causing the seepage and infiltration of water to be unmanageable, and

b) there is no control on the underground spoilage due to activities of micro-organism.

Improved Ginger storage structure

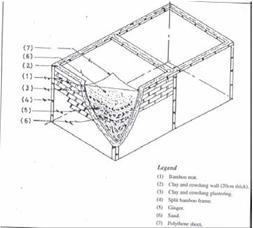

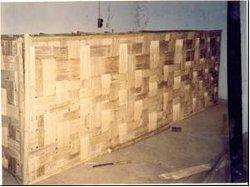

Considering the availability of local material an improved storage-structure for ginger was developed by ICAR Research Complex for NEH Region, Barapani, Meghalaya. It was an indoor structure. The raw material required for the structure consisted of bamboo, clay, cow dung, sand, polythene sheets and galvanized wire. The main components of the structure are clayed bamboo mat wall, split bamboo frame, sand and polythene sheet.

The schematic and skeleton of the clayed-bamboo wall ginger storage structure is presented in figures. The structure has two chambers of size 2 m x 2 m x 1.4 m (height). The walls of the structure were made of bamboo mat, clay and cowdung. The thickness of the wall is 20 cm; it is double walled with its frame made of bamboo & GI wire. The clay and cowdung paste was poured in the gap of the wall in 4-5 stages at regular intervals with a one day interval up to the complete height (1.4m) of the walls. This filling was kept for drying continuously for 20-25 days. The outer surfaces of the walls were plastered with clay and cowdung paste. After drying the structure is ready for storage of ginger.

Method of storage

The ginger was stored in this chamber by alternate layer of dry sand and rhizomes with keeping the thickness ratio of 2.5: 10 cm. The lower and upper layer of sand was kept around 8 cm thick. The top of the chamber was covered with the polythene sheet and sealed from the edges by putting more pressure with the help of split bamboo.

Advantages of using this structure

Ginger was kept for five months in such structure. It was observed that there was (a) no loss in weight and moisture, (b) no sprouting took place, (c) no loss due to any infestation and rotting and (d) the quality of rhizomes was also maintained. The structure proved perfect for storing the rhizomes till the period of further sowing. The capacity of the storage in such structure was approximately 4 tonnes of rhizomes. The unit capacity of the structure was evaluated as 350 to 400 kg per cubic meter of space.

Cost, Durability and Maintenance of the Structure

The cost of such a structure may vary from place to place according to the availability of bamboo and labour. However, the storage structure constructed in Meghalaya costs around Rs. 2000/-. The approximate break up of the cost was;

(a) material cost (bamboo, polythene sheet and wire) Rs. 1000/- and

(b) Labour cost (mat preparation and erection of clayed bamboo wall) Rs. 1000/-.

The minimum 30% loss incurred by pit storage was spared by this new technique. Thus the structure returned the cost of 1.2 tonnes of rhizomes. The rhizome rate at the time of sowing season varies from Rs. 20 to 40 per kg, which gives the 30% more return than by storing by the pit method. The unit cost of storage came to Rs. 0.50/kg. The structure was used for the following year after a minor repair and wall plastering. Such a structure might last for 4 to 5 years unless there is a major damage. Great care should be taken to save the structure from rodents and termites so that it lasts long.

Last Modified : 3/1/2020