Threshing

Threshing

What is threshing?

“Threshing” is the operation of separating the grains from the plants. These operations may be carried out in the field or on the threshing floor, by hand or with the help of animals or machines. Whatever the system used, it is very important that threshing be done with care. Otherwise, these operations can cause breakage of the grains or protective husks, thus reducing the quality of product and subsequent losses from the action of insects and moulds. Care should also be taken while transporting the harvested crops from the field to threshing floor to avoid any loss.

Hand Threshing

Hand threshing is generally done in case of pigeonpea. One of the simplest systems for threshing of pigeonpea crop is to strike the sheaves of crop spread over threshing floor with a flail or a stick. While this method can be adopted for other pulse crops like chickpea, mungbean, urdbean, fieldpea, rajmash and lentil but a more convenient method is threshing with animals or vehicles. The threshing-floors on which the sheaves are spread must have a hard, clean surface. By using method of hand-threshing, a worker can obtain 15-40 kg of product per hour.

Threshing with Animals or Tractors

Subject to the availability of draught animals, large quantity of crops can be threshed by treading the animals over about 30 cm thick layer of sheaves. This operation, which is also called “treading out”, can equally well be accomplished with vehicles. Grain is obtained by running the tractor twice over sheaves of harvested and dried crops that are spread in layers on a circular threshing floor 15-18 m in diameter. The sheaves must be turned over between the two passages of the tractor.

Threshing with hand driven machines

Normally a hand-operated machine like Olped thresher, which is basically used for threshing of paddy can also be used for threshing of cut stocks of pigeonpea. By means of the handle or pedal, a big drum fitted with metal rings or teeth is made to rotate. The cut-stocks of pigeonpea is threshed by hand-holding the sheaves and pressing the upper portion of dried plants against the rotating drum. The speed of the threshing drum must be kept at about 300 revolutions perminute (rpm). The hand-held sheaves must all be of the same length with the panicles all laid in the same direction, and the grains must be very ripe and dry. The machine must be continuously and regularly fed, but without introducing excessive quantities of product. Use of these threshing machines may require two or three workers. Depending on the type of machine, the skill of the workers and organization of the work, yields can be estimated at a maximum of 100 kg/h.

Threshing with Motorized threshers

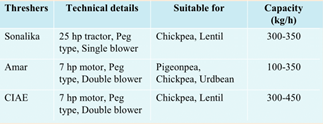

The use of motorized threshers or threshers operated by tractor power has become very common for threshing of pulse crops. The threshers available in the market are basically designed for threshing of cereal crops and no specific thresher is available for threshing of pulse crops. However, by the simple replacement of a few accessories and the appropriate changes in settings, these machines can be used for threshing of pulse crops as well. Few popular designs of cereal threshers like Amar thresher, CIAE Multicrop thresher and Sonalika threshers have been successfully used for threshing of pulse crops with some degree of variations in the grain recovery. Table shows the principal technical features of these machines and the yield obtained in case of different crops. Equipped with a rotating threshing drum (with beaters or teeth) and a stationary counter-thresher, these machines often have devices to shake out the straw and to clean and bag the grain. Whether self-propelled or tractor-drawn, these threshers are often mounted on rubber wheels for easy movement to the field. The use of motorized threshers may require two or three workers. Yields depend on the type of machine, the nature and maturity of the grain, the skill of the workers and organization of the work.

Threshing capacity of different threshers

Last Modified : 2/19/2020