Value addition in Pineapple

Value addition in Pineapple

Pineapple in Meghalaya

Pineapple (Ananas comosus) is non-climacteric fruit grown widely in Meghalaya. It is rich in vitamin C, magnesium calcium, potassium, iron and the protein digesting enzyme, bromelin. Kew and Queen are the two promising cultivars of pineapple In North East India. Kew variety is characterized by the big sized fruits (1.5-2.5 kg) which are oblong and tapering slightly towards the crown. The flesh is light yellow and very juicy when ripe. Queen variety fruits are of the weight 0.9-1.3 kg in general. The flesh is deep golden-yellow less juicy than Kew, crisp textured with a pleasant aroma and flavour. Pineapple plants flower 10-12 months after planting and fruits become ready 16-18 months after planting. In natural condition it is harvested during May-August. Fruits which mature in the winter are acidic. The fruits with crown can be kept for 10-15 days after harvesting.

Pineapple Juice

It is the juice extracted from pineapple that can be marketed by bottling in to sterilized bottles or can. By adding preservative at a specified level (KMS <70ppm or Benzoic acid < 120 ppm), the shelf life of the juice can be extended to 6-7 months. Flow chart for preparation of pineapple juice is shown below:

|

Slices from under-sized pineapple fruits, broken slices, cores, peel meat and trimmings |

|

Crushing/pulping (Mixer grinder) |

|

Juice extraction with the help of muslin cloth |

|

Filling into glass bottles & sealing with hand sealer |

|

Processing in boiling water (15-20 minutes at 85oC) |

|

Cooling |

|

Labeling & Storing |

Pineapple Squash

Pineapple squash should be prepared from fully matured and sound pineapple fruits free from insect infestation, diseases etc. For preparation of pineapple squash required quantity of juice, sugar, citric acid, preservative (Potassium metabisulphite or sodium benzoate), water, essence and colour are calculated as per FPO specifications. It should be diluted 2-3 times with water at the time of consumption. Flow chart for preparation of pineapple squash is shown below:

|

Slices from under-sized pineapple fruits, broken slices, cores, peel meat and trimmings |

|

Crushing/pulping (Mixer grinder) |

|

Juice extraction with the help of muslin cloth |

Mixing of syrup with juice

|

Syrup |

|

Sugar + Water + Clitric Acid |

|

Addition of permitted essence, colour & preservatives |

|

Mixing |

|

Bottling and Capping |

|

Labelling |

|

Storing |

Recipe for Pineapple Squash :

|

Sl.No |

Raw materials |

Quantity |

|

1. |

Pineapple Juice |

1.0 kg |

|

2. |

Sugar |

900g-1.2g |

|

3. |

Water |

1.3 liter |

|

4. |

Citric acid |

40-45 g |

|

5. |

Pineapple Colour |

0.5 g |

|

6. |

Pineapple essence |

5-10 ml |

|

7. |

Potassium meta bisulphite(KMS) |

Not more than 1.0 g/kg |

Pineapple Ready-to-Serve (RTS) Beverage

The pineapple RTS beverage is prepared from the extracted pineapple juice, adjusting its soluble solids and acidity as per FPO specifications for RTS beverage by mixing the juice with required quantity of sugar syrup prepared from sugar, citric acid and water. Colour and essence as per the requirements are also added and mixed thoroughly. The beverage is filled into bottles leaving a head space of 2.5 to 3.0 cm, crown corked and processed in water for 15-20 mins at 85oC and air cooled. Flow chart for preparation of Ready-to-Serve Beverage is shown below:

|

Slices from under-sized pineapple fruits, broken slices, cores, peel meat and trimmings |

|

Crushing/pulping (Mixer grinder) |

|

Juice extraction with the help of muslin cloth |

Mixing of syrup with juice

|

Syrup |

|

Sugar + Water + Clitric Acid |

|

Addition of permitted essence, & colour |

|

Mixing |

|

Bottling and Sealing |

|

Processing in boiling water (15-20 minutes at 85oC) |

|

Storing |

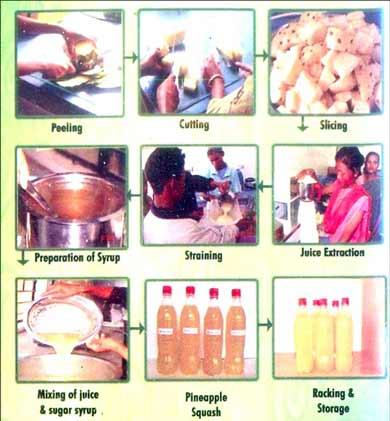

Steps to be followed during Pineapples squash preparation

Recipe for Pineapple (RTS) Beverage

|

Sl.No |

Raw materials |

Quantity |

|

1. |

Pineapple Juice |

1.0 kg |

|

2. |

Sugar |

600-700g |

|

3. |

Water |

4.0 liter |

|

4. |

Citric acid |

10-15 g |

|

5. |

Pineapple Colour |

1.5 g |

|

6. |

Pineapple essence |

15-20 ml |

Pineapple Jam

Pineapple jam is solid gel made from the fruit pulp or juice, sugar, and pectin. Different steps which are essential during this product preparation is shown below :

|

Pineapples (Fresh and firm fruits) |

|

Peeling, removal of eyes, core |

|

Cutting into small pieces & crushing |

|

Addition of sugar & citric acid (1.0-1.4 kg sugar/kg product & 5-10 g citric acid) |

|

Heating for 15-25 min. |

|

Addition of Pectin powder (3.5-5.0 g/kg product) |

|

Test for end point |

|

Addition of colour and essence (optional) |

|

Filling in sterilized glass jars while hot |

|

Cooling for 4-5 hours |

|

Sealing and storing |

Recipe for Pineapple Jam:

|

Sl.No |

Raw materials |

Quantity |

|

1. |

Pineapple Pulp |

1.0 kg |

|

2. |

Sugar |

1.0-1.4g |

|

3. |

Citric acid |

10-15 g |

|

4. |

Pectin powder |

3.5-5.0 g/kg |

|

5. |

Pineapple Colour |

1.5 g |

|

6. |

Pineapple essence |

5-10 ml |

Precautions

- All the processing steps should be done under hygienic conditions

- Only potable water should be used

- During jam making the pulp should not be overcooked

- The specifications for the minimum use of additives should be strictly followed

FPO Specifications

|

Products |

Min. % of total soluble solids in the final product wt. |

Min. % of fruit juice in the final product |

Min. ppm of preservative to be used |

|

Squash |

40 |

25 |

SO2 ≤ 350 or Benzoic acid ≤ 600 |

|

Sweetened Juice |

Natural |

100 |

SO2 ≤ 350 or Benzoic acid ≤ 600 |

|

RTS |

10 |

10 |

SO2 ≤ 70 or Benzoic acid ≤ 120 |

|

Jam |

68 |

45 |

SO2 ≤ 40 or Benzoic acid ≤ 200 |

For more details contact : Director, ICAR Research Complex for NEH Region, Umiam Meghalaya – 793 103

Phone no. 0364- 2570257 (o), Fax no. 0364 - 2570355

Source: Pamphlet published by ICAR Research Complex for NEH Region, Umiam, Meghalaya

Last Modified : 7/5/2024

Provides information about the National Mission fo...