Biogas Generation, Purification & Bottling Development In India – A case study

Biogas Generation, Purification & Bottling Development In India – A case study

Biomass resources such as cattle dung, agriculture wastes and other organic wastes have been one of the main energy sources for the mankind since the dawn of civilization. There is a vast scope to convert these energy sources into biogas. Biogas production is a clean low carbon technology for efficient management and conversion of fermentable organic wastes into clean cheap and versatile fuel and bio/organic manure.

Biogas Composition and Properties

Biogas comprises of 60-65% methane, 35-40% carbon dioxide, 0.5-1.0% hydrogen sulphide, rests of water vapours etc. Biogas is non-toxic, colour less and flammable gas. It has an ignition temperature of 650 - 750oC. Its density is 1.214kg/ m3 (assuming about 60% Methane and 40% CO2). Its calorific value is 20 MJ/m3 (or 4700 kcal.). It is almost 20% lighter than air. Biogas, like Liquefied Petroleum Gas (LPG) cannot be converted into liquid state under normal temperature and pressure. It liquefies at a pressure of about 47.4 Kg/cm2 at a critical temperature of - 82.1o C. Removing carbon dioxide, Hydrogen Sulfide, moisture and compressing it into cylinders makes it easily usable for transport applications & also for stationary applications. Already CNG technology has become easily available and therefore, bio-methane (purified biogas) which is nearly same as CNG, can be used for all applications for which CNG are used. Purified biogas (bio-methane) has a high calorific value in comparison to raw biogas.

Technology Demonstration on Biogas Bottling under RDD&D

First time in the country during the year 2008-09, a new initiative was taken for technology demonstration on biogas bottling projects in entrepreneurial mode, for installation of medium size mixed feed biogas plants for generation, purification and bottling of biogas under Research, Development, Demonstration, and Deployment (RDD&D) policy of Ministry of New and Renewable Energy (MNRE) after R&D.

Installation of such plants aims at production of CNG quality of Compressed Biogas (CBG) to be used as vehicular fuel in addition to meeting stationary & motive power, electricity generation, thermal application etc. needs in a decentralized manner through establishment of a sustainable business model in this sector. There is a huge potential for installation of such plants in various areas. Under the demonstration phase, the Ministry has sanctioned a central financial assistance for a limited number of such projects for implementation following an entrepreneurial mode in different states namely Chhattisgarh, Gujarat, Haryana, Karnataka, Maharashtra, Punjab, Madhya Pradesh, Andhra Pradesh and Rajasthan.

About 11 numbers of biogas bottling projects of various capacities and technologies have been commissioned in the country after obtaining required licenses for filling and storage of compressed biogas in CNG cylinders from Petroleum & Explosives Safety Organization (PESO), State Pollution Control Board (PCB) etc. IIT, Delhi is assigned for technical monitoring & handholding of the consultants/promoters and preparation of documentation on different types of technology which may emerge out of these projects.

The details of commissioned biogas bottling projects are given below:

| Sl. No | State | Name of the project / organization | Capacity of the plant (m3 /day) | Estimated production of CBG (kg/day) |

|---|---|---|---|---|

| 1 | Maharashtra |

1. Mr. N.C. Mujumdar 1 Director Ashok Biogreen Pvt. Ltd., Vill. Talwade, Tahasil Trimbak, Dist.-Nasik |

500 | 200 |

| 2. Dr. A. V. Mohan Rao, Director M/s Spectrum Renewable Energy Pvt. Ltd., Vill. – Kodoli, Block –Panhala, Warana nagar, Dist.–Kolhapur Email. – info@srel.in | 20000 | 8000 | ||

| 2 | Punjab | 3. Dr. Ashwini Kumar Watts Promoter Anand Energy, Vill.-Kalatibba, Teh.-Abohar, Dist.- Ferozepur Email: anandenergy@ymail.com | 600 | 240 |

| 4. Shri Sachin Dhawan Partner SASK Energy, Vill.-Najabt Kukrian, P.O. Lubaniawali, Tehsil & Dist. – Muktsar Email: sachin.dhawan86@gmail.com | 1000 | 400 | ||

| 5. Ms. Seema Garg Partner Sanjh Deep Gas Energy, Vill./P.O.-Mehma Sarja, Tehsil- Bhatinda, Dist. - Bhatinda Email: sanjhdeepgroup@gmail.com | 5000 | 2000 | ||

| 3 | Karnataka | 6. Mr. T. Anand Director Maltose Agri Products Pvt. Ltd., Vill.- Huskur, Post -Aralumallige, Tal.- Doddaballapur, Dist.- Bangalore rural E-mail: a9880039666@gmail.com | 1000 | 400 |

| 4 | Haryana | 7. Mrs. Jyoti Marya Partner Shashi Energies, Near Green Vally Public School, Ratiya Road Tohana, Tehsil.- Tohana, Dist.- Fatehabad Email: maryadeepak@gmail.com | 600 | 240 |

| 8. Mr. Abhay Sinha, Managing Director Option Energy Pvt. Ltd, Shree Haryana Gaushala, Vill.&Block – Hansi, Dist. Hisar Email - abhaysinha12@hotmail.com | 1000 | 400 | ||

| 9. Shri Raj Paul Midha Director 21st Century Enviro Engineers (P) Ltd. Vill.- Begu, Block– Sirsa, Dist. – Sirsa Email: century_21@sify.com | 4216 | 1686 | ||

| 10. Mr. Amit Kadian Partner Amit & Sumit Dairy Farm, Vill.- Jahajgarh, Tehsil-Beri, Dist.- Jhajjar Email: kadianmilkpoint@gmail.com | 700 | 280 | ||

| 5 | Rajasthan | 11. Shri Din Dayal Singla, Partner Singla Bio-Energy, Vill.-Siaghawali, Tehsil–Sadulsehar, Dist.–Sri Ganganagar Email - singlabioenergy@gmail.com | 1000 | 400 |

The purity of biogas is more than 90% Methane and this has being corroborated through tests conducted by National Accreditation Board for Testing and Calibration Laboratories (NABL) and compressed to 150 bar pressure for filling in cylinders.

The purified biogas is equivalent /similar to CNG. The purified biogas is filled in CNG cylinder and supplied to mid-day meal scheme, mess, Hotel, industries etc. for various purposes such as cooking & heating etc. Calorific value of purified biogas is equivalent / similar to CNG. As a matter of fact, the biogas bottling plants are one of the most potent tools for mitigating climatic change by preventing black carbon emission from biomass chulha since biogas is used as a cooking fuel and methane emissions from untreated cattle dung and biomass wastes are also avoided. The purified biogas can be bottled in CNG cylinders and wherever CNG is currently used, biogas bottling can be used as an alternative.

The slurry which comes out of the biogas plant is directly or after drying used as bio/organic manure for improving soil-fertility and reducing use of chemical fertilizers. It is also non-pollutant because it is free from weed-seeds, foul smell and pathogens. The slurry is rich in main nutrients such as Nitrogen, Potassium and Sodium (NPK) alongwith micronutrients - Iron & Zinc etc. As such there is no pollution from biogas plant. The slurry/manure of biogas plant is being sold to the farmers and used in liquid/solid form by them in agricultural crops. The field trials have indicated the excellent growth in agro-production and substantial improvements in the quality.

Payback Period

The Biogas bottling project of 1000m3 /day capacity installed at Singla Bio-Energy, Vill.– Siaghawali, Teh.-Sadulsehar, Dist.–Sri Ganganagar (Rajasthan) with the investment of Rs. 1.95 crore by the promoters. The viability of the project is given below:

| Sl. No | Particulars | Amount (Rs. in lakh) |

|---|---|---|

| I | Expenses in one month | |

| 1 | Raw Materials | 1.55 |

| 2 | Electricity | 0.12 |

| 3 | Labour | 0.64 |

| 4 | Bank loan & interest | 3.75 |

| 5 | Miscellaneous | 0.83 |

| II | Income in one month | |

| 1 | Compressed Biogas | 8.05 |

| 2 | Organic Manure | 1.75 |

| III | Profit | |

| 1 | Monthly | 2.91 |

| 2 | Annualy | 34.92 |

| IV | Payback period | |

| 1 | Without subsidy | 5 to 6 years |

| 2 | With subsidy | 3 to 4 years |

This biogas bottling project will be able to replace fuel & manure worth of about Rs. 35 lakh annually. The full cost of the project would be recovered within four to six years. The separation and bottling of CO2 and extraction of Humic acid from slurry would further improve viability of biogas bottling plants. The biogas bottling project provide three-in-one solution of gaseous fuel generation, bio /organic manure production and wet biomass waste disposal/management.

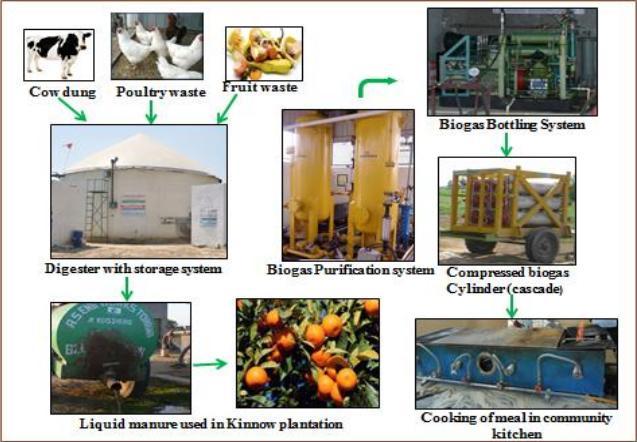

The schematic diagram of the Biogas bottling project 1000m3 /day capacity installed at Singla Bio-Energy, Vill.–Siaghawali, Teh.-Sadulsehar, Dist.–Sri Ganganagar (Rajasthan) is given below:

Source : MNRE

Last Modified : 3/2/2020

This topic provides information about Rajasthan So...

A description of how energy availability and acces...

This section contains the database of all producti...